Smparticle2 - Untitled

More Posts from Smparticle2 and Others

:)

「Howls Moving Castle (2004) {+color palletes} 」insp.

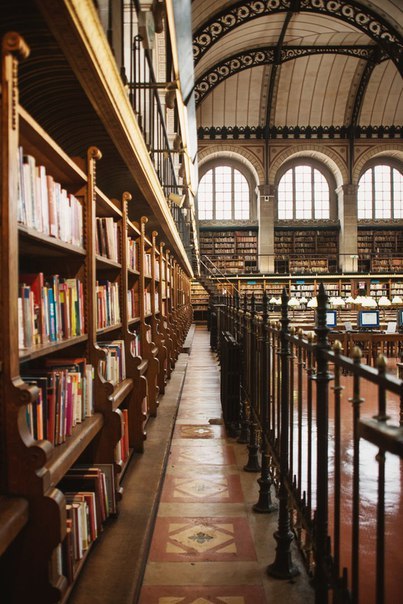

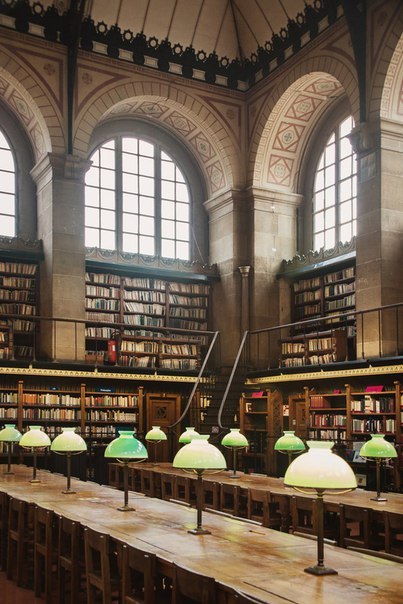

Sainte-Geneviève Library. Paris, France.

That Moment… My Heart…

(Photo Credit: Kenneth Jarecke/Contact Press Image)

Bringing silicon to life: Scientists persuade nature to make silicon-carbon bonds

A new study is the first to show that living organisms can be persuaded to make silicon-carbon bonds – something only chemists had done before. Scientists at Caltech “bred” a bacterial protein to make the humanmade bonds – a finding that has applications in several industries.

Molecules with silicon-carbon, or organosilicon, compounds are found in pharmaceuticals as well as in many other products, including agricultural chemicals, paints, semiconductors, and computer and TV screens. Currently, these products are made synthetically, since the silicon-carbon bonds are not found in nature.

The new study demonstrates that biology can instead be used to manufacture these bonds in ways that are more environmentally friendly and potentially much less expensive.

“We decided to get nature to do what only chemists could do – only better,” says Frances Arnold, Caltech’s Dick and Barbara Dickinson Professor of Chemical Engineering, Bioengineering and Biochemistry, and principal investigator of the new research, published in the Nov. 24 issue of the journal Science.

Read more.

Moonlight

When a porous solid retains its properties in liquid form

Known for their exceptional porosity that enables the trapping or transport of molecules, metal-organic frameworks (MOFs) take the form of a powder, which makes them difficult to format. For the first time, an international team led by scientists from the Institut de recherche de Chimie Paris (CNRS/Chimie ParisTech ), and notably involving Air Liquide, has evidenced the surprising ability of a type of MOF to retain its porous properties in the liquid and then glass state. Published on October 9, 2017 in Nature Materials website, these findings open the way towards new industrial applications.

Metal-organic frameworks (MOFs) constitute a particularly promising class of materials. Their exceptional porosity makes it possible to store and separate large quantities of gas, or to act as a catalyst for chemical reactions. However, their crystalline structure implies that they are produced in powder form, which is difficult to store and use for industrial applications. For the first time, a team of scientists from the CNRS, Chimie ParisTech, Cambridge University, Air Liquide and the ISIS (UK) and Argonne (US) synchrotrons has shown that the properties of a zeolitic MOF were unexpectedly conserved in the liquid phase (which does not generally favor porosity). Then, after cooling and solidification, the glass obtained adopted a disordered, non-crystalline structure that also retained the same properties in terms of porosity. These results will enable the shaping and use of these materials much more efficiently than in powder form.

Read more.

-

alcrux87 reblogged this · 3 weeks ago

alcrux87 reblogged this · 3 weeks ago -

unmarrow liked this · 1 month ago

unmarrow liked this · 1 month ago -

sword-hearted reblogged this · 1 month ago

sword-hearted reblogged this · 1 month ago -

itsmeimcathy reblogged this · 1 month ago

itsmeimcathy reblogged this · 1 month ago -

chaoticacecryptid reblogged this · 1 month ago

chaoticacecryptid reblogged this · 1 month ago -

slasherslut883 liked this · 1 month ago

slasherslut883 liked this · 1 month ago -

plaid-lover-bay25 liked this · 2 months ago

plaid-lover-bay25 liked this · 2 months ago -

abbessolute reblogged this · 2 months ago

abbessolute reblogged this · 2 months ago -

toomanyfandomsshreya reblogged this · 3 months ago

toomanyfandomsshreya reblogged this · 3 months ago -

toomanyfandomsshreya liked this · 3 months ago

toomanyfandomsshreya liked this · 3 months ago -

phoenix-maat reblogged this · 3 months ago

phoenix-maat reblogged this · 3 months ago -

abbessolute reblogged this · 3 months ago

abbessolute reblogged this · 3 months ago -

lovleyladylavender liked this · 3 months ago

lovleyladylavender liked this · 3 months ago -

zannenilsson liked this · 3 months ago

zannenilsson liked this · 3 months ago -

ashtreenomy reblogged this · 3 months ago

ashtreenomy reblogged this · 3 months ago -

ashtreenomy liked this · 3 months ago

ashtreenomy liked this · 3 months ago -

dumbmischief liked this · 3 months ago

dumbmischief liked this · 3 months ago -

evixerat liked this · 3 months ago

evixerat liked this · 3 months ago -

anon55mystery liked this · 3 months ago

anon55mystery liked this · 3 months ago -

spiralwaves reblogged this · 3 months ago

spiralwaves reblogged this · 3 months ago -

honest-trifles liked this · 3 months ago

honest-trifles liked this · 3 months ago -

phoenix-is-still-here liked this · 3 months ago

phoenix-is-still-here liked this · 3 months ago -

sparklynarwhal7 liked this · 3 months ago

sparklynarwhal7 liked this · 3 months ago -

thelamp2 liked this · 3 months ago

thelamp2 liked this · 3 months ago -

saiph-orionis reblogged this · 3 months ago

saiph-orionis reblogged this · 3 months ago -

saiph-orionis liked this · 3 months ago

saiph-orionis liked this · 3 months ago -

rabidfirefoxfan reblogged this · 3 months ago

rabidfirefoxfan reblogged this · 3 months ago -

rabidfirefoxfan liked this · 3 months ago

rabidfirefoxfan liked this · 3 months ago -

hornyjail-inmate liked this · 3 months ago

hornyjail-inmate liked this · 3 months ago -

guiltybystanders liked this · 3 months ago

guiltybystanders liked this · 3 months ago -

idonutknowyet liked this · 3 months ago

idonutknowyet liked this · 3 months ago -

ghost-note-symphony reblogged this · 3 months ago

ghost-note-symphony reblogged this · 3 months ago -

ladyofthestayingpower liked this · 3 months ago

ladyofthestayingpower liked this · 3 months ago -

madsam06 liked this · 3 months ago

madsam06 liked this · 3 months ago -

psychicluminary reblogged this · 3 months ago

psychicluminary reblogged this · 3 months ago -

psychicluminary liked this · 3 months ago

psychicluminary liked this · 3 months ago -

pinkypkmntrainer liked this · 3 months ago

pinkypkmntrainer liked this · 3 months ago -

gummy-reblogs reblogged this · 3 months ago

gummy-reblogs reblogged this · 3 months ago -

gummy-axolotl liked this · 3 months ago

gummy-axolotl liked this · 3 months ago -

saiyanlion reblogged this · 3 months ago

saiyanlion reblogged this · 3 months ago -

saiyanlion liked this · 3 months ago

saiyanlion liked this · 3 months ago -

rocket-220 reblogged this · 3 months ago

rocket-220 reblogged this · 3 months ago -

rocket-220 liked this · 3 months ago

rocket-220 liked this · 3 months ago -

ostrich-runner liked this · 3 months ago

ostrich-runner liked this · 3 months ago -

tangyyrine liked this · 3 months ago

tangyyrine liked this · 3 months ago -

westrangecollectionkoalaposts reblogged this · 3 months ago

westrangecollectionkoalaposts reblogged this · 3 months ago -

westrangecollectionkoalaposts liked this · 3 months ago

westrangecollectionkoalaposts liked this · 3 months ago -

lentalguts-gingersnaps liked this · 3 months ago

lentalguts-gingersnaps liked this · 3 months ago -

starweird03 liked this · 3 months ago

starweird03 liked this · 3 months ago